Old Meccano parts can be easily restored to shine like

new and save great expense on the purchase of new or

replica parts. I have successfully used the following

methods to restore hundreds of old damaged parts

Many Meccano enthusiasts have piles of old parts lurking

in boxes that are serviceable but not like they were when

new. Why not bring these parts back into use? The first

thing to do is sort through your old parts and identify which

are worth the time and effort. Moderately bent parts can be

coaxed back into straightness using a combination of

fingers, metal working vice, hardwood blocks and a

hammer. Avoid striking the Meccano hard with a hammer

as this will further distort the part, Meccano parts are made

of soft mild steel that easily stretches and distorts. If you

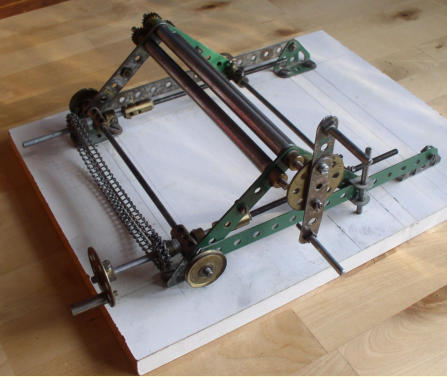

have a strip roller this can be of great use in smoothing out

bent parts, run the parts through several times turning over

at each pass. All Meccano builders should have one of

these tools for curving strips and plates you always get a

nice even curve and when used the parts can be curved

back to be straight. The rollers can found sometimes on

dealers websites or on eBay.

Badly distorted and twisted parts are often beyond

restoration but it worth looking to see if these parts could

be cut down, for instance 25 hole girders can be cut down

to less common and more expensive parts such 15 or 18

hole girders. The same applies to strips and flat girders

note that 15, 18 and 25 hole strips are made of thicker

steel than the other strip lengths. Cutting down can easily

be done by putting the parts in a metal working vice and

cutting though with a fine blade hacksaw. Shorter thin

strips can also be cut with aero shears. It can be a help to

use another old part as a guide bolting it over the part you

wish to cut down. Once cut the end can then be curved by

clipping off the corners at 45 ° then using a flat file or

bench mounted grindstone shape to a curve. Once this is

done use a fine file to smooth and remove burs then finish

off with fine grade emery paper (wet and dry paper).

Removing the old paint

Your collection of parts should now be stripped of their paint; this can be done using caustic soda. Caustic soda is also know as Sodium

hydroxide or lye. Lye is sold in North America as an ingredient for making soap. All chemicals and paint removers are hazardous so

please use extreme caution using these. Make sure you wear strong rubber gloves and eye protection and use in a well-ventilated

area. Caustic soda is relatively cheap and can be reused. I mix no more than a litre at a time, mix in an old plastic container (not clear

types), fill this with cold or luke warm water and add a few table spoons of the soda. DO NOT USE HOT WATER this causes a reaction

with the soda and gives off dangerous fumes. Please note never add water to the soda powder when mixing. Another warning DO

NOT use aluminum containers the caustic soda will after a while destroy these.

The parts should be left for at least 15 minutes, during this time make sure the parts are agitated to keep them separated. Stubborn

paint can be left overnight. Remove the parts wearing strong rubber gloves and thoroughly rinse and clean under hot running hot

water. The parts should now be dried using an old towel and then put in a warm oven or left out in the sun to dry. (see picture above)

The parts will probably now have some fine hair lines of rust on them this should all be removed using fine steel wool. The parts should

not be allowed to become damp and if not going straight on to painting should be put somewhere dry and warm. If you are not keeping

the caustic soda this can be safely poured down a sink drain as it is sold as drain cleaner. If there is any rust left on the parts this can

be treated using rust remover deeply pitted badly rusted parts are not worth treating.

Zinc and Nickel

Old zinc parts often become very dull, tarnished or have white effervescence on the surface this can be cleaned up by rubbing down

with very fine steel wool. Lime scale cleaners containing phosphoric acid can also clean zinc parts but leave only for a few minutes

unles you are going to paint the parts. I have found this method works well on zinc nuts and bolts too. Zinc and nickel parts with light

tarnishing finger prints and discolouration can be effectively polished using metal polish such as Brasso or Autosol these are also

brilliant on brassware.

Leaving as plain metal

Another thought at this point is to just polish the parts this can be done using fine steel wool, scotch bright pads or a fine wire wheel on

an electric drill. Although every imperfection in the parts will show. The parts can then be polished with a silicone spray furniture polish

and buffed up with a yellow polishing duster, I have quite a lot of parts that I have used this method on and they have remained rust free

over many years of use.

I find it a good idea to polish up rods with fine steel wool this makes for much smoother running in bearings. Some rods are made of

very soft steel and can become damaged by tightened bolts the rods can be smoothed off with emery paper or course steel wool and

finished off again with fine steel wool

So far I have been talking about constructional parts , similar methods can be used for braced girders, perforated, flexible and flanged

plates. Flexible plates though are more difficult to get flat if bent several times or with sharp bends, again a plate roller can be a big

help. However creased parts are best discarded unless they can be cut down to a smaller size avoiding the crease. It can be useful to

have a collection of old plates when building a model that requires bending of plates these can bent to experiment with before using a

good quality part for the model.

Colour finished parts produced in the past few years are thickly powder coated, this is quite difficult to remove but some commercial

paint strippers will remove this. Some of the recent parts have a foil covering this can be lifted off using a sharp craft knife.

Spraying

Before spraying parts should be thoroughly clean with no trace of dirt or grease, it's a good idea to wipe them over with a cleaning cloth

soaked in white spirit, then dry with a lint free cloth.

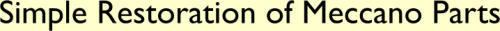

I use a wooden frame with wire fitted into slots to support my parts for spraying (see picture above). Follow the instructions on the spray

can, it is always best to build up THIN coats do not over spray. When the parts are touch dry turn them over and spray the other side. It

is important to spray in a warm dry atmosphere do not spray when there is high humidity. Please take care spraying and always wear a

face mask of the type available in DIY and hardware stores. Should the spray noozle have become blocked next time you use the paint

this can be cleared by soaking in caustic soda do thoughly soak in water before using.

Leave for at least six hours to become “air dry” check at this stage to see if any more coats are required. If not the parts should now be

baked to harden the paint. I use a fan oven pre-heated to 150c. Using the Plastikote paint I have never found any residual smell but

please check with other users of the oven first. On no account should you bake parts at the same time as cooking in the oven! Place

the parts on a special unpainted metal mesh rack making sure they do not touch each other and place in the oven, leave for no longer

than 10 -12 minutes, the parts can be stored away or be ready for use as soon as they have cooled, although I usually leave them for a

few days before using.

DARK BLUE AFTER SPRAYING

Some UK Paint matches for Meccano colours

If you want to match Meccano colours there are not too

many exact matches here are some that I have used

recently. I much prefer to use enamel paint. Other options

are to get the colours matched by a spray paint supplier,

enemel paint is better the car paint.

Plastikote Royal Blue 680 a very close match to 1978 Binns

Road dark blue. A batch of these parts baked dark blue parts

shown on the right. Note the colour in the picture is not

representative of the painted parts, they are much darker.

Plastikote Bright Red 1120 is a good match for mid nineteen

fifties red I found that a better finish was obtained by using

Plastikote grey undercoat before spraying the red.

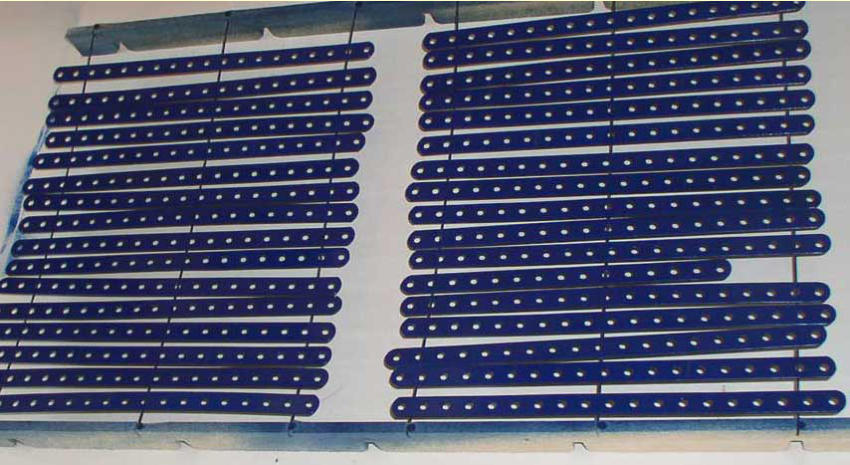

Plastikote Industrial “Rust-Not” Emerald Green 788 is a fairly

good match for mid nineteen fifties green. Shown on the letf

just after removal from the oven. This colour is no longer

available in gloss but only matt. Hard Hat Emerald green

2136 is very similar and available in gloss.

B&Q have a spray paint that is a close match to early 1970's

yellow 'Marigold' Painter's Touch range (400ml) aerosol. I did

not find this as durable as the Plastikote paint

Plastikote Pacific blue is a close match for early 1970's mid

blue although slightly lighter and not such a deep colour.

Plastikote "Brass" a very good match for the pre-war gold. If

over-sprayed with clear matt varnish looks almost exactly

the same.

BS 381C – Crimson 540 – 400ml Custom Filled Aerosol

Spray Paint Can is a good match for 1928-1934 dark red,

shown on the left.

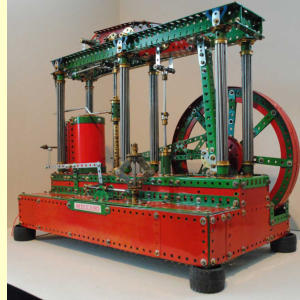

My beam engine above , rotating big wheel, road sweeper,

jumbo crane and nineteen thirties models use parts that

have been restored using the method I have discribed

Below is a batch of parts in pre-war red and gold air drying

awaiting baking. The gold colour is Plastikote "Brass" a very

good match for the pre-war gold. The red road wheel rims

are sprayed with Plastikote Bright Red.

Useful non-standard easily made parts.

A very common part, number 215 the slotted curved strip can be made into two useful parts not produced by Meccano. The first is to

simply straighten it out this makes a useful 3” flat strip the slotted holes give versatility on cross bracing or can be used to make up a

non standard strip length. The second is to make the flattered strip into a double angle strip I made this to fit inside the cylinder part

number 216. Non stand ardlengths can be cut from strips and girders, remember strips above 11 holes are thicker guage steel.

Non standard double angle strips can some times be useful, Meccano never made 6 x 1 hole and 4 x 1 hole sizes although other

four hole and six hole parts are in the standard range of parts. These can be easily made from old 6,7,9 or 11 hole strips, and you

could end up with a few bonus three hole strips too!

I hope my hints were useful to you as always pleased to hear from you.

Page originally created August 12 2011 Revised July 28 2022

THE PLATE & STRIP ROLLER I USE