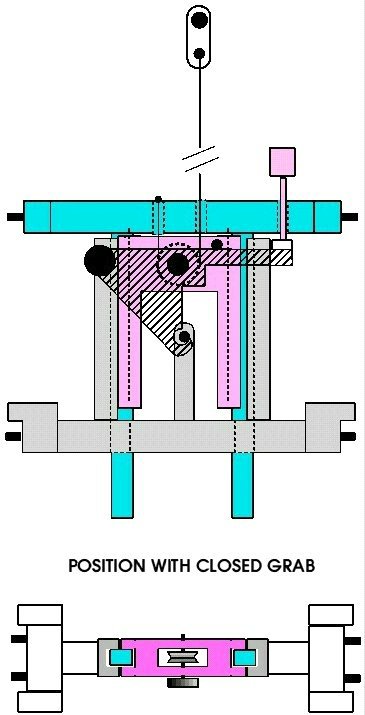

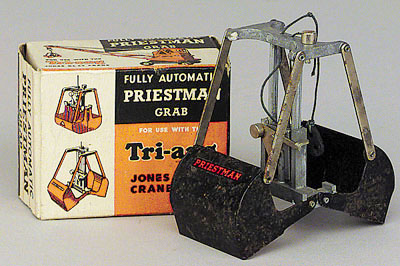

The original Triang grab is shown above, mine is finished in matt black with nickel plated arms, the main part of the mechanism is die cast . The grab was also available in gloss orange or gloss black finish.

How it operates

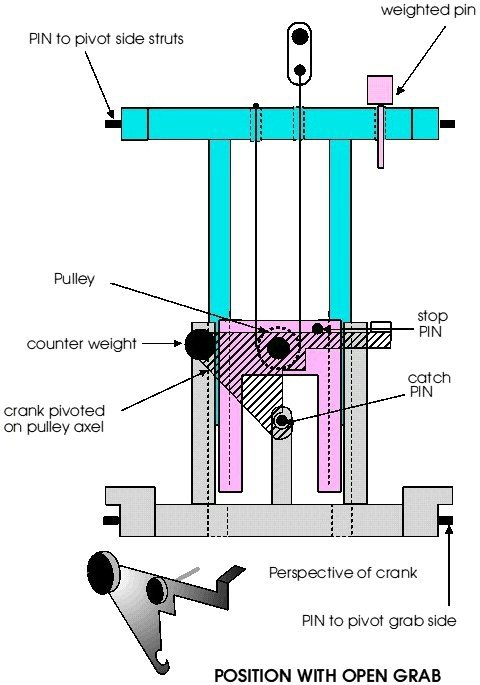

.

The sides

of the grab buckets are connected to the bar at the BOTTOM of

the drawing. (also see the photos). The bucket side struts are connected to

the TOP bar, in such a way that when the grab is lifted by the bottom

bar, the grab closes; and when it is lifted by the top bar, the grab

opens. This arrangement is common to most Meccano grab mechanisms. The

assembly between

the two bars is free to slide up and down, and is connected to the

hoisting

rope.

As the grab is lowered in the open position, it touches the ground and further lowering of the rope allows the sliding assembly to descend under its own weight until the pivoted catch on this assembly latches over the pin on the bottom bar. (see drawing 'position with open grab')

When the grab is raised, the sliding assembly is drawn up, bringing the bottom bar up with it, therefore closing the grab and lifting the whole thing off the ground. The weight of the grab buckets on the bottom bar tends to hold the latch closed, so that as the horizontal lug on the pivoted catch rises to meet the weighted pin, the pin is lifted up. (see drawing 'position with closed grab')

When the grab is next lowered and touches the ground, the weight of the grab buckets is removed from the latch, and as the sliding block starts to descend under its own weight, the latch is released by the weighted pin falling. When the cord is lifted again, the weighted pin remains in the depressed position to prevent the latch from re-engaging. The grab is now lifted by the top bar and the bucket opens again. So the cycle repeats.

The weight of the pin would be quite critical, as it has to overcome the effect of the counter weight when the catch is free to pivot, but not so heavy that it releases the catch when the weight of the bucket is on the latch.

It looks like the grab would still work if the cord was simply tied off on the sliding block, without passing around a pulley. Although the effect of the loop in the cord is to pull the two bars against each other in order to close the grab when the latch is engaged and the cord hoisted.

Although this description is a bit long-winded, the grab is delightfully simple to watch in operation.

Illustrations drawn by Alan Esplen. Explanatory text by Melvyn Wright

Grab shown with original packaging and Priestman transfer.

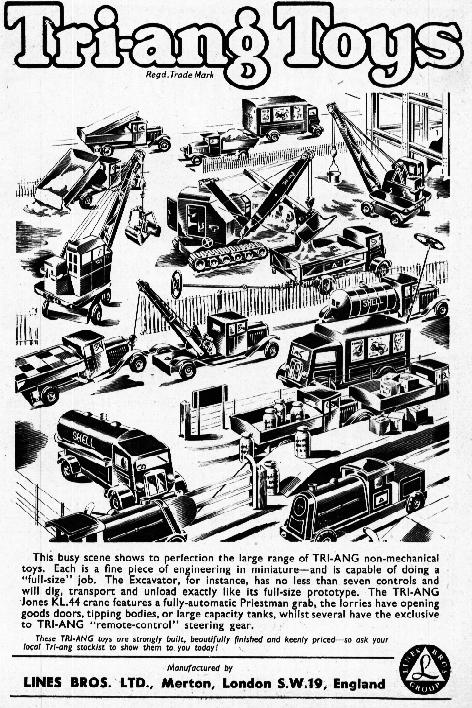

The toy

(model) Jones KL44 crane

was bought for me by my parents in the early nineteen fifties and is now 59 years old

(October 2009).

The crane was originally supplied with a black glossy metal bucket now

long lost, the grab

was bought as an extra. The robustness of the Jones crane is hard to believe in our age of plastic throw away toys. The lever at the rear of the crane is one of a

pair that lock the winding

drum and jib in position on a ratchet wheel.

The black and White picture below is an advertisement for Triang Toys that was published in The Meccano Magazine in the early 1950s and dates from the time of the introduction of the Jones KL44 crane.

The KL derives from Kryn and Lahy Jones two Belgium refugees, who set up a steel foundry at Letchworth in 1915. Jones cranes were manufactured between 1938 - 1995 by Kryn & Lahy Steelfounders and Engineers Ltd. Their huge range of mobile cranes were exported all over the world.

For further information on Triang Toy cranes click this link

![]() Back to Alan's Main Meccano page.

Back to Alan's Main Meccano page.

Revised July 27 2012